Server-Online

400-1133-638

13925536251

Intermediate frequency ion coating machine

Magnetron sputtering coating machine

Intermediate frequency multi-arc ion plating

Metal coating machine

Tableware coating machine

Lighting coating machine

Clock coating machine

Ball Equipment Coating Machine

Bathroom coating machine

Sanitary Ware Coating Machine

Vacuum coating equipmentPVD coating equipment

PVD vacuum coating equipment

Intermediate frequency ion coating machine - Diestand splash coating equipment

ICO -Plane ion coating machine:

The equipment sets DC sputtering, the three technologies of the mid -frequency sputtering and the evaporation of the arc ions are integrated and integrated. According to the needs of different products, the heating system, partial pressure system, and ionization system can be selected according to different product needs. The device is equipped with many pairs of intermediate frequency targets, which can be plated with metal products and non -metal surface -plated alloy membranes, compound membranes, multi -layer composite membranes, etc., and it is conducive to rapidly depositing and thicker and pure membrane layers.

Equipment model:

| model | Inner cavity | Remark |

|

TYL0608 |

Φ600*H800(mm) |

Device can be customized according to customer requirements |

|

TYL1009 |

φ1000*H900(mm) |

|

|

TYL1112 |

φ1100*H1250(mm) |

|

|

TYL1312 |

φ1300*H1250(mm) |

|

|

TYL1612 |

φ1600*H1250(mm) |

|

|

TYL1912 |

φ1900*H1250(mm) |

|

|

TYL1914 |

φ1900*H1400(mm) |

|

|

TYL1422 |

φ1400*H2200(mm) |

Equipment advantage:

The membrane layer plated in the device has the advantages of strong adhesion and high denseness, and provides solutions for improving color consistency and the stability of compound composition. Hardness meets the needs of high -performance membrane layers. The product is manifested as corrosion resistance, increased elastic modulus of the membrane layer hardness, lower friction coefficient on the coating surface, and increased light brightness of the coating.

Preparation of coating:

Ion gold, ion silver, titanium nitride film, titanium titanium film, nitride film, titanium aluminum alloy film, chromium nitride (TICN), (TIC), (TIO2), (TIALN), (CRN), (CRN), (CRN), (CRN) ), (ZRN), (CRC) and other metallic compound layers.

Product Features:

Effect: The firmness of the composite membrane (functional membrane) is high and high. High icon rate, high deposition rate, low temperature and stable sputtering of magnetic control, delicate particles, simple operation, high yield, etc.

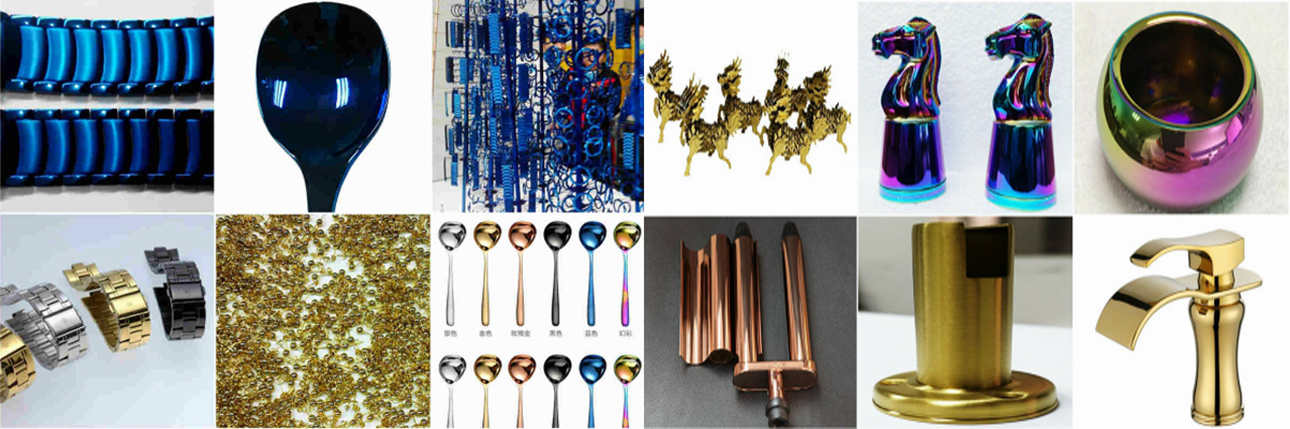

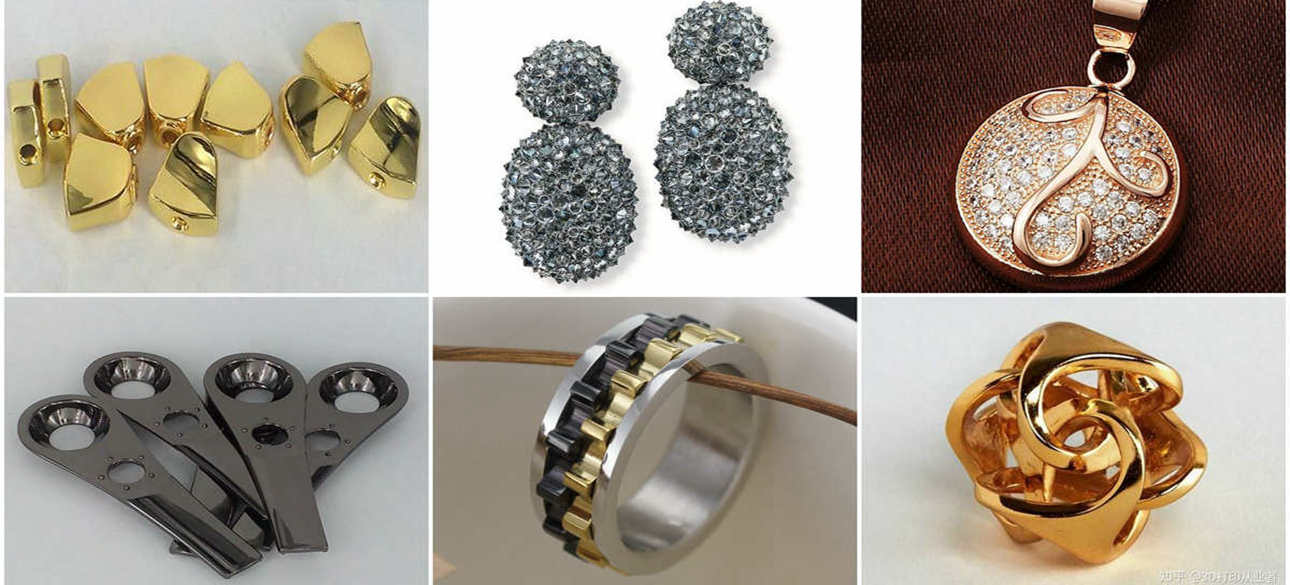

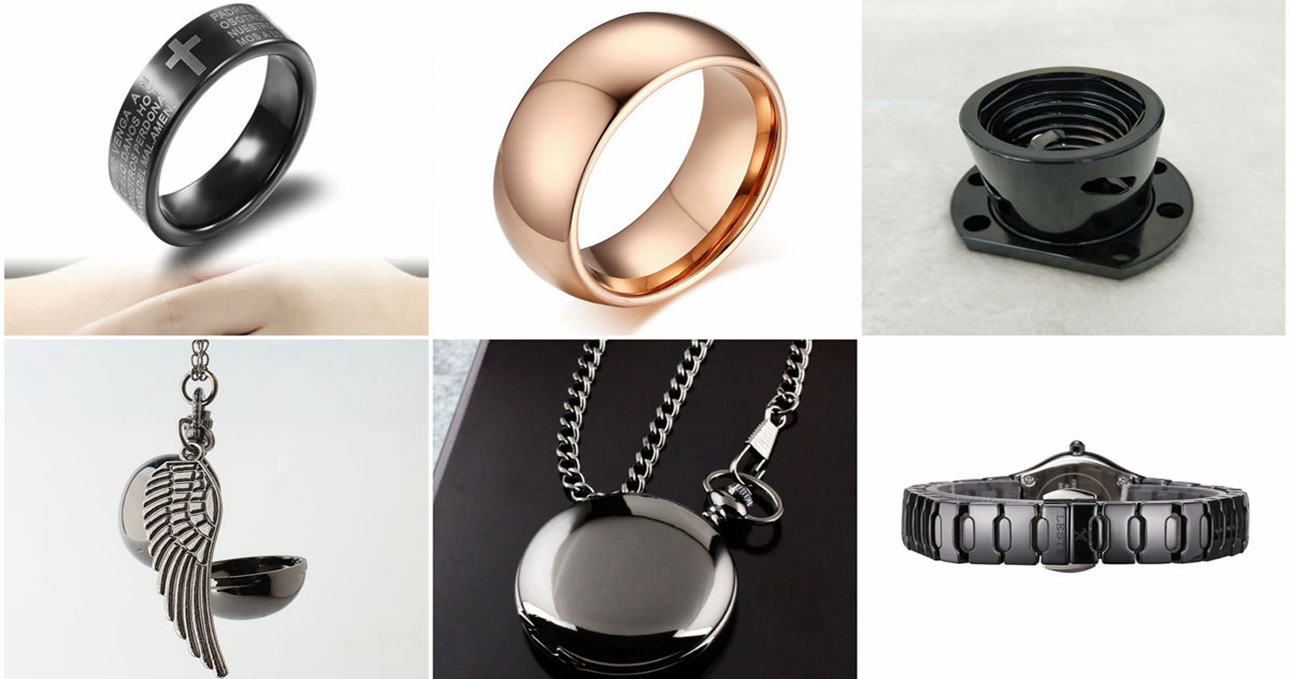

Equipment application:

Belt, golf balls, hardware, tableware, watch accessories, mobile phone accessories, glasses racks, lighting, sanitary ware and other high -end products.

Plating color:

Titanium series, golden series, brushed series, black series, and color film layer series can achieve more than ten colors such as dark black, gold, rose gold, imitation gold, gold, gem blue, bright silver.

Example of coating:

Dingyi Technology

The company can design a variety of specifications of vacuum coating machines according to the user's requirements.

Vacuum units and electrical control systems can also be designed and configured according to user requirements.

Dingyi provides a leading internationally -in -level coating application solution: provides system services such as equipment, materials, processing, technology, and project support.

Dingyi real vacuum coating equipment: evaporate coating machine, magnetic control sputtering coating machine, magnetic control evaporation dual -use coating machine, multi -arc ion coating machine, frequent ion coating machine, AF coating machine, ultra -hard coating coating machine, PVD coating coating, PVD coating coating Line, PVD coating project supporting assembly.

PVD process technology is used under vacuum conditions to deposit various metals and non -metallic membranes on the surface of plastic parts by distillation or sputtering.

Dingyi Technology matches the best coating process according to the characteristics of the product.

Dingyi vacuum coating machinery and equipment in the industry advantage: professional, honest, and reliable.

300 meters southwest of Jindu Police Station, Century Avenue, Jindu Town, Gaoyao District, Zhaoqing City, Guangdong Province, China

+86 400-1133-638

+86 13925536251 (Mr. Deng)

380236471@qq.com

Copyright © 2022 Zhaoqing Dingyi Technology Co., Ltd